With a wave of a magic wand, I take you back in time

Imagine you wake up in your quaint Cotswold cottage, the year is 1773. You make your way into the main room, squeezing past the immense dobby loom. This state of the art weavers loom takes up most of the cottage’s space with its 4x3x4 meter frame. You yawn, stretch and make your way over the gruel that’s left for you. Your partner and the kids have already gone to work in the Fulling Mill nearby.

Imagine you wake up in your quaint Cotswold cottage, the year is 1773. You make your way into the main room, squeezing past the immense dobby loom. This state of the art weavers loom takes up most of the cottage’s space with its 4x3x4 meter frame. You yawn, stretch and make your way over the gruel that’s left for you. Your partner and the kids have already gone to work in the Fulling Mill nearby.

It’s the start of the new era. The invention of the flying shuttle now means you can man your loom alone; no help needed. This increases the work that you can do in a day. You taste the future and the world seems full possibilities.

You eat finish your gruel, get dressed and start work. You push the lever down with your foot, pull the release for the shuttle and beat down the threads.

Push, pull and beat. Push, pull and beat. Push, pull and beat. Push, pull and beat…

On and on. After an hour, you stretch your muscles, they ache, it’s always the same, always in the same spots. But what can you do, the fabric has to be made. You know firsthand, having learned the hard way – that you need to keep a rhythm, so the cloth remains even. You need to keep a steady tandem going for the rest of the day. That will be for another 13 hours. You start to sing your favourite rhyme; it’ll keep you going and give you a steady beat to work by. It’s only 13 more hours, just like it was yesterday and just like it will be tomorrow:

Push, pull and beat. Push, pull and beat. Push, pull and beat. Push, pull and beat…

With a wave of a wand, I take you back to the present.

Are you tired yet? I felt tired when I saw the looms and heard how many hours the weavers once worked. They worked on looms so big that it left no room in the cottage for furniture. Which, considering people worked 14 hour days, there was little to no time for lounging anyway.

I learned all about the history and process of weaving on a recent tour of two Mills in Nailsworth. Located in the once prosperous Cotswolds valleys of the United Kingdom. The last tour, of Ebley Mill, covered the local history and the building itself. While, the tours of Gigg and Dunkirk Mill go more into the art of weaving and making cloth, as well as its evolution over time.

Learning to Weave at Gigg Mill

I am not new to weaving, as I have done workshops in the past. Yet, nothing that could have prepared me for the size of the Looms at Gigg Mill. Our tour guide taught us about the process and terminology before letting us try out hand on the smaller loom. He then demonstrated how the flying shuttle works on the larger loom. John Kay invented the shuttle back in 1973, pretty high tech for the time.

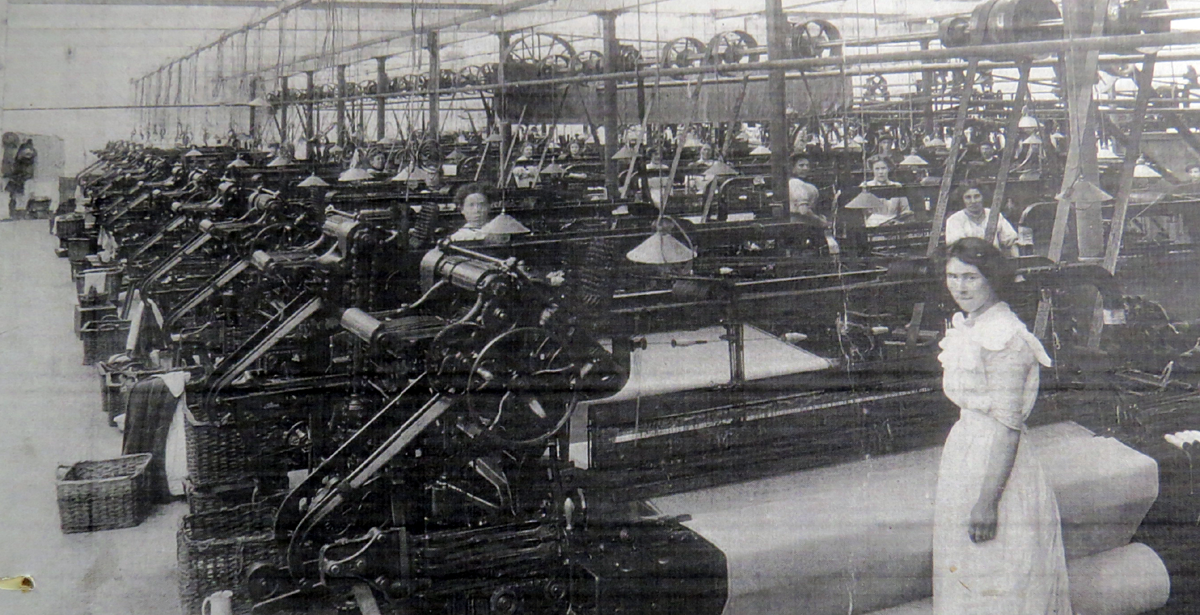

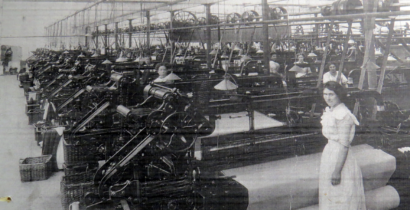

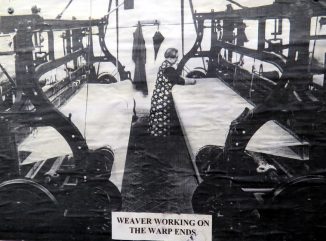

There is also a machine loom on site, which once again sped up the process of weaving, as you can see in the photos the were mills full of them. We saw it in briefly in action, what a heavy, noisy affair.

A Quick stop for Photographs at Egypt Mill

While Egypt Mill isn’t part of the tour. It is a stunning refurbishment of an old Water Mill into a bar, restaurant, and hotel. While in all honesty the food and coffee were below par – it is still worth stopping at for a few photos.

I recommend walking from Gigg Mill to Dunkirk, you not only get to pass Egypt Mill on the way. But the path itself is a picturesque footpath/bike lane and part of the famous Cotswold way. It weaves through the trees and alongside the river that would have once powered the Mills.

Finishing off the Cloth at Dunkirk Mill

In recent years, Durnkirk Mill has been transformed into stunning apartments. A caveat for getting planning permission was to keep on of the old water wheels functioning as it once did. And to allow the Stroudwater Textile Trust to run a small museum in the building.

It in this museum we get to learn about the last steps in the process for making cloth. We learned about Fulling; that bangs and squashes the cloth. This binds the fiber together, creating a thicker, felt like cloth. There are two machines, the guide turned one on for a few seconds. Which was a complete assault on the senses.

It is so loud and violent that it leaves my teeth clattering, and their vibrations echoing through my skull. I have no idea how anyone could be anywhere in the vicinity, let alone work there day and night. I am not surprised to hear that those that worked in the mill were deaf.

But, the next machine was still a finer invention than the one before, which had you stomping in a barrel. Similar to making wine. Only instead of grapes, they added ammonia and fullers earth. Which doesn’t sound too bad until you hear at the time the natural ammonia would have been urine. So, not sure if I would rather be stomping in urine or deaf… Not great choices.

Thankfully, there were newer improved inventions that followed.

A Power of a Water Mill in Action

It was an incredible thrill to see the large water mill turned on (see video below). Its exceptional bulk  takes up much of the space. Luckily it is well protected to stop anyone falling in. Its power vibrates through the entire room. You can’t help but wonder what it would have been like with four of these wheels turning and all the machines in action.

takes up much of the space. Luckily it is well protected to stop anyone falling in. Its power vibrates through the entire room. You can’t help but wonder what it would have been like with four of these wheels turning and all the machines in action.

At present the mill powers two machines; a modernised version of the fulling machine. The second raises the cloth by stroking the fabric with a teasel brush. Teasels are part of a plant that looks like a burr-weed. These were put into the brush by a special teasel setter.

The photo here is of the last teasel setter, who has since passed away. I always find it sad that complete knowledge of a craft can die with someone. An age-old specialism that will no longer be passed on down and through generations.

The photo here is of the last teasel setter, who has since passed away. I always find it sad that complete knowledge of a craft can die with someone. An age-old specialism that will no longer be passed on down and through generations.

The fluff from the teasels was cleared off the brush by children. A sure sign that they worried somewhat less about health, safety or child labor back in the day.

The shearing the cloth

One of the last treatments in creating such a fine cloth was the shaving off any excess fibres. A tough job and a dangerous skill. Should you get it wrong you’d not only ruin the cloth but also lose a body part.

Later, they evolved this action into a rotating machine you see in the photo here. Which coincidently lead to the invention of the lawnmower. Obviously, the cloth wasn’t the only thing that needed to be kept in good order.

Last sentiments on the woven fabric of our Textile History

It was a huge thrill to see the Mills in action and to learn so much about the whole weaving and cloth making process.

There is a part of me that is sad about losing the craftsmanship and knowledge of the industry as machines take over and production moved overseas.

There are only a few working mills left here in the United Kingdom. One of them is nearby, making high-quality cloth for professional billiard tables.

While nostalgic for the loss of an era. I question the work and physical effort, and side effects of working in the mill. I don’t believe I could with those machines going night and day.

I prefer weaving as a hobby, same as knitting, something I do in small quantities for the pleasure and joy of it. I am sure those who were weaving for 14 hours a day, or working in the factory would have had that luxury.

Still, the textile industry made a difference to the economy. Whether it was for ships sails, with which to go off and discover faraway shores. Blankets, uniforms to the very clothes that have kept us humans warm for centuries.

For me, it will always be a magical process. The weaving together of thread to create a piece of cloth. A cloth that can then be cut, sewn and fitted into endless possibilities.

It brings to mind the mythology of the Moirai (The 3 fates), who spun together each person’s destiny at the moment of birth.

With this magic, perhaps we can weave together a future, where we keep the craftsmanship. While finding new ways to make fabric, in a more sustainable and harmonious way. Thankfully, trends like the slow fashion movement are attempting just that.

The tours put on by organisations such as the Stroudwater Textile trust help to share the knowledge, passion, and history with us. So that these stories are remembered, acknowledged and passed on.

A big warm-hearted thank you to our guide, who worked in the industry all his life, and who was incredibly knowledgeable. Thank you to the Stroudwater Textile Trust for organising these tours at such affordable prices. For opening and sharing the stories and heritage of these Mills with us.

If you’d like to do a tour yourself, check out their website for times and availability.

For those wishing to learn more about the stories of the Mill, I’ve just found a book and tv series about life of the children in the Cotton Mills further north in the UK. Fascinating read, and TV series which was based on a few of the stories that came out of the archives:

A great story!! Fabulous photographs……..love it xxxx